Sustainability and Technology

Commitment

Identifies the products that comply with our company's commitment to the sustainable origin of the materials and treatments we use.

On average, more than 80% of the impact of a product (textile and accessories) is due to the materials from which it is made. This is why the selection of materials and accessories for each product is an essential part of TERNUA GROUP's environmental strategy. The goal? Durable, high-performance products that are, above all, harmless to people and the environment.

In 2007, we introduced an internal sustainable design standard that allows us to guide and support our teams' progress in product development called COMMITMENT, which is now used by all of the group's brands.

The product development teams of each brand are fully aligned and work continuously to improve and develop this commitment.

For a product to be identified as COMMITMENT, it must meet one of the following conditions.

It must be designed and manufactured with:

-Recycled materials.

-100% organic cotton materials, grown without the use of genetically modified seeds, chemical fertilizers or toxic and persistent pesticides.

-Biodegradable renewable materials (wool, Tencel®..).

-Bluesign or Oeko-tex standard 100 certified materials. These certifications help us to select and identify the most responsible materials.

BLUESIGN

Certificate that guarantees that approved fabrics meet even stricter and more extensive requirements with respect to the chemicals used in the production of our materials. This means greater safety for the production process, the environment and consumers.

OEKO-TEX

It guarantees that certified fabrics do not contain chemicals that are harmful to the health of the people who manufacture and use them and to the environment.

SINGULAR PROJECTS

SARETU - REDCYCLE

The garments contain 100% recycled nylon from fishing nets resulting from the SARETU collaboration project, based on collecting in the port of Seychelles the nets discarded by Basque tuna fishing boats operating in the Indian Ocean, providing a solution through the circular economy to the problem of discarded fishing gear.

REDCYCLE:

It is a project to collect and recycle, in cooperation with Aquafil, disused fishing nets to bring them back to life and turn them into sustainable garments… and committed to a better future. We partnered with the Italian company Aquafil, a pioneer in a unique recycling process that allows us to transform disused nets, along with other Nylon waste materials through the ECONYL® regeneration process, into ECONYL® regenerated yarn.

LATXA ARTILE

The garments under the Latxa Artile project contain an insulation made from the wool of the Ardi Latxa sheep, guardian of our landscape, providing a high-value solution to a material that is considered waste.

WEARCYCLE

Wearcycle is a project that transforms post-consumer textile waste into timeless and durable garments. Our penchant for design and honest fashion has led us to collect garments that are at the end of their life cycle for the production of recycled yarn to make new products. The aim is to use damaged clothes from laundries and to produce recycled yarn. A project based on the principle of circular economy with which we create functional and quality garments.

TECNOLOGÍAS

WARMSHELL

THERMOREGULATOR

Warmshell fabrics are manufactured from quality raw materials and created using advanced technology to achieve the highest level of functionality. Prevents heat loss, keeps the body warm and protected.

- Excellent heat retention without increasing weight.

- Fast drying

- High breathability

- Excellent durability

- Easy care

WINDSHELL

Windshell fabric combines wind protection with high breathability thanks to its 10K/10K membrane. Designed to be a mid or outer layer to minimize body heat loss on exposure to wind.

SHELLTEC

Shelltec fabric combines waterproofing and breathability with a breathable windproof barrier thanks to its membrane (water column -10,000 mm and vapor permeability 10,000 g/m2/24h). Designed to be an outer layer, Shelltec fabric is developed to minimize heat loss on exposure to water and wind. This fabric is perfect for outdoor activities when bad weather demands high external protection.

MICROSHELL

The Microshell technical fabric is technologically developed based on ultra-fine synthetic microfibers, which makes it an ultra-light, highly breathable, windproof fabric. It contains a PFC (Fluorocarbonate) free water repellent treatment. It is also resistant to feather and fiberfill.

NEOKDUN RECYCLED DOWN

"Recycled down and feathers come from used bedding and garments that have reached the end of their useful life. Normally, down and feather fillings have a longer shelf life than the finished products themselves. Therefore, feather and down fillings are extracted from these products. The feather and down filler material is sorted and processed to meet cleanliness standards and other performance requirements. The recycled down and feathers can then be used to refill other finished products.

ARTILESHELL

"The inner padding, called ARTILESHELL, and responsible for providing insulation and maintaining body heat, is made of pure Latxa sheep wool, totally natural, sustainable and biodegradable. A product as simple and pure as it is sophisticated and technological.

It manages and controls humidity.

It absorbs interior perspiration and repels moisture from the outside, achieving exceptional comfort and performance in adverse weather conditions.

The rapid expulsion of moisture from the wool prevents the appearance of bad odors and bacteria.

Thermoregulator: maintains body temperature."

TRATAMIENTOS

PFC FREE DWR

PFCs are synthetic compounds whose properties provide waterproofing and non-stick properties to the outer surface of fabrics. However, they are highly toxic and when released in small doses from garments, they seriously pollute the environment. At Loreak Mendian, we have eliminated their use by looking for equally effective and biodegradable alternatives.

Últimos post

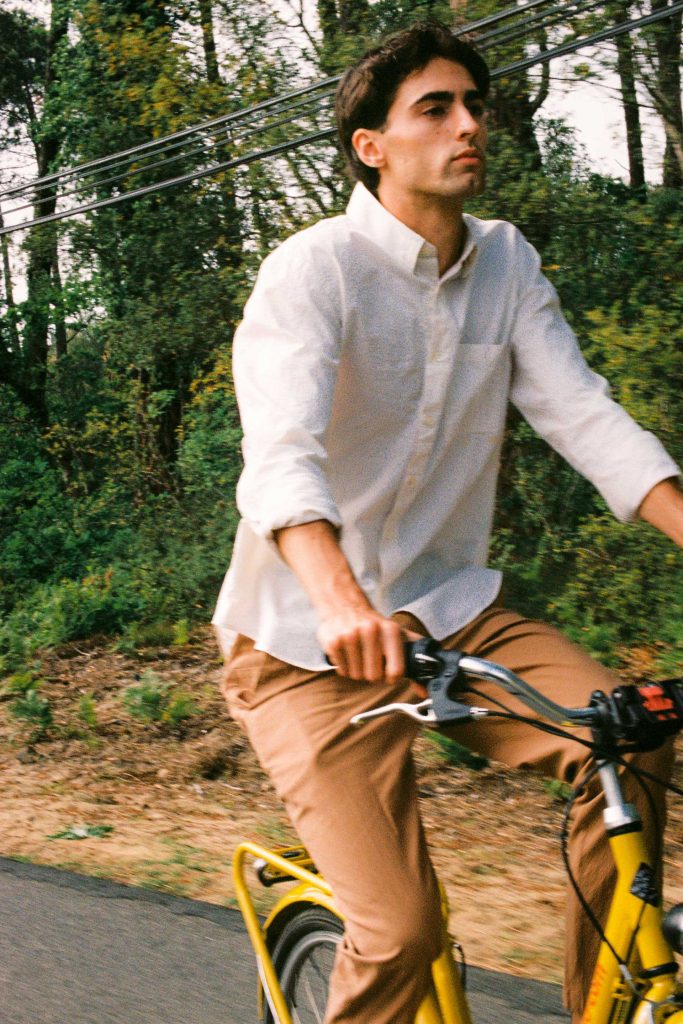

- SS24 Men LookbookMen's spring-summer 2024 lookbook for the season

- SS24 Women LookbookWomen's spring-summer 2024 lookbook for the season

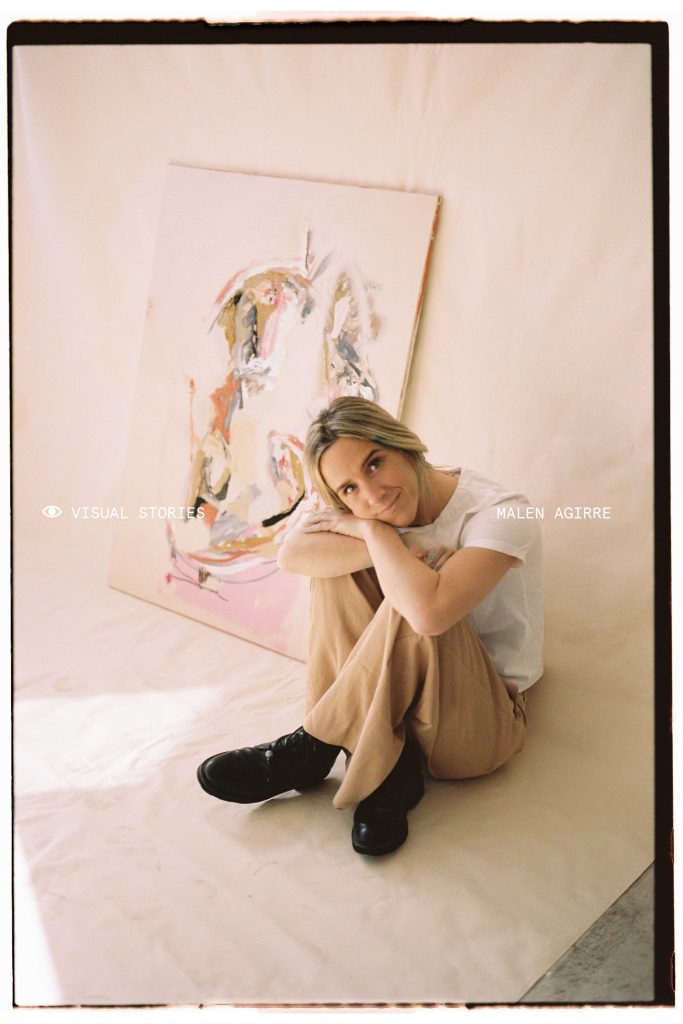

- Visual Stories — Malen AgirreWe interviewed Malen Agirre, print designer and painter, in our Visual Stories questionnaire.

- Visual Stories — Lander IbarretxeThe filmmaker Lander Ibarretxe, author of many of the pieces created in Loreak Mendian, answers our questionnaire.